|

|

|

|

|

|

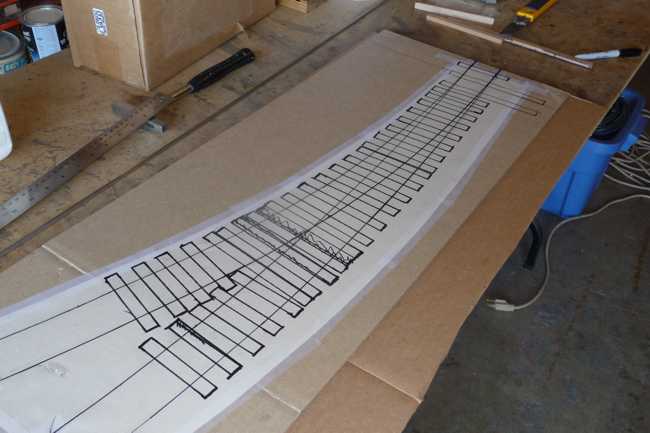

A custom fitted curved turnout

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustments to track plans happen regularly and even more frequently in the garden. The plan called for a conventional RH turnout, but as the roadbed went in it became obvious that a curved turnout would “flow” much nicer.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To make the process as easy and convenient as possible the first step was temporarily installing a piece of flextrack with the one profile extending farther forward to blend into the existing track.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Next came a large sheet of paper, carefully fastened with transparent tape, so that the inner edges of the tracks could be traced.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Trim the sheet of paper and attach to a piece of corrugated cardboard, with an additional piece of cardboard to make sure that there would be enough clearance for the spikes to clear.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Then it was time to re-trace the tracklines with a felt pen using a piece of rail as a flexible ruler.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Marking the positions of the different ties and setting them in place - with plenty of adhesive - was the next step.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Anchor screws are used at various important location and the screw threads are secured with some GEL-CA. Once the screws are set the heads are tinned with solder.

|

|

|

|

|

|

|

|

|

|

|

Next page

|

|

|

|

|

|