|

|

|

|

|

|

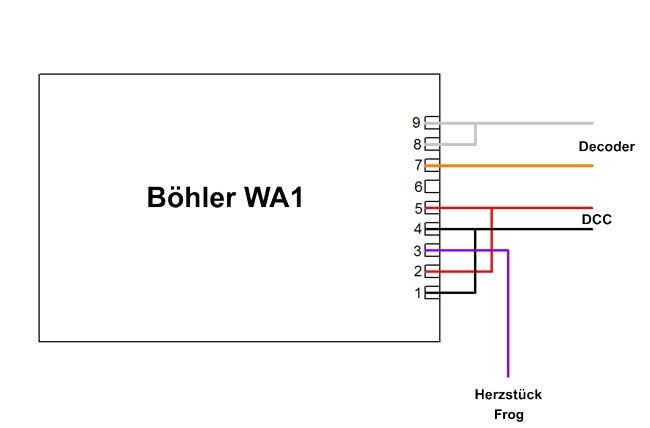

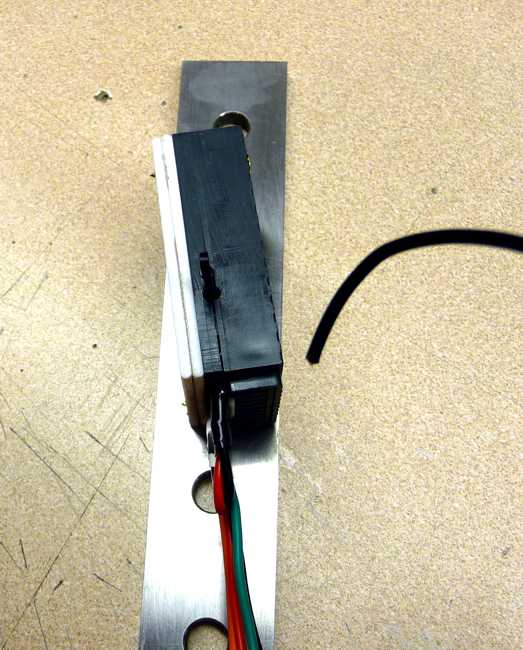

Böhler WA1 controlled by ZIMO MX82V

|

|

|

|

|

|

|

|

|

The excellent experiences and recommendations of others were the deciding factor. On our layout the powered turnouts - other than in staging - are limited to two per station. Just enough to enable meets and passing in each station and the basic necessity for the CTC that is planned.

|

|

|

The items come with detailed instructions for a number of different DCC and analog systems - but ZIMO wasn’t among those. A search of the Internet produced some hits, but unfortunately not the correct ones. It was time for the trial and error routine. The second variation was the sought version.

|

|

|

|

|

|

|

|

|

Connection schematic

|

|

|

|

|

|

|

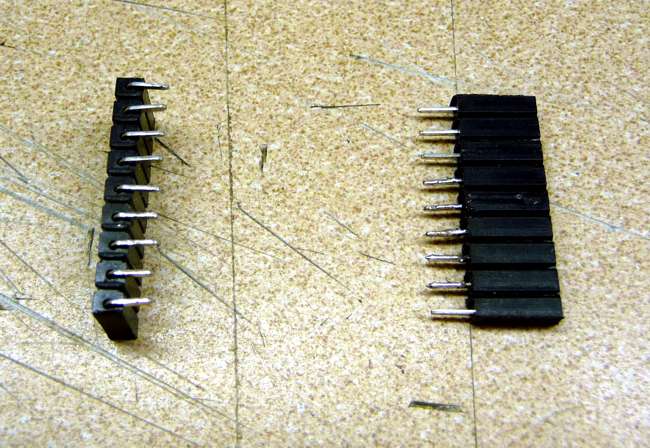

At times even good products can be improved. The plug as delivered is such an instance; bending the connector pins by 90º will improve the ease of connect and disconnect quite a bit.

|

|

|

|

|

|

|

|

|

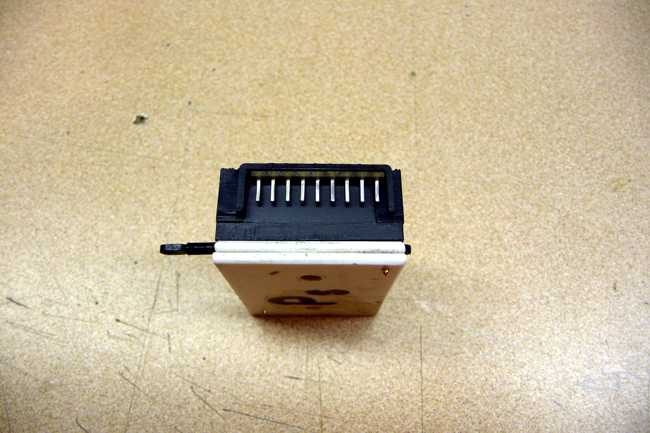

Modified plug

|

|

|

|

|

|

|

To align the actuating rod of the machine with the throwbar - with the rod being above the throwbar - a 4mm spacer/mounting plate is used.

|

|

|

|

|

|

|

|

|

Spacer/mounting plate

|

|

|

|

|

|

|

|

Position of actuating rod and throw bar

|

|

|

|

|

|

|

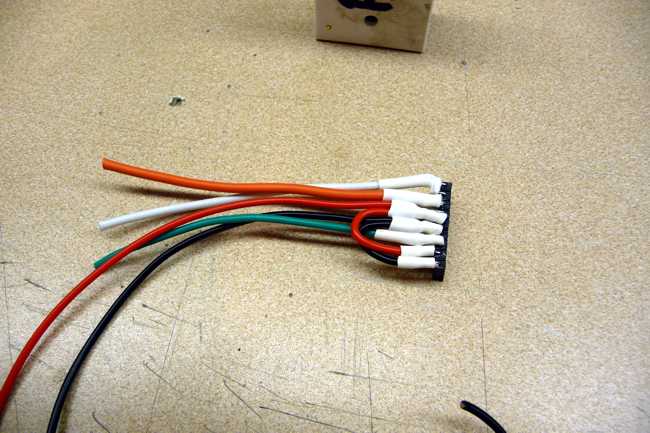

The DCC power comes directly from the turnout rails, a two conductor cable connects to the decoder. Preprogrammed for assembly on the work bench.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The modification results in enough extra space to connect and disconnect the plug once the turnout motor is fixed in place.

|

|

|

|

|

|

|

|

|

Plugged in connector

|

|

|

|

|

|

|

Careful alignment and marking of the position

|

|

|

|

|

|

|

|

|

Mounting of the spacer plate

|

|

|

|

|

|

|

A simple “Link and Pin” arrangement connects the actuating rod with the throwbar.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Link and Pin

|

|

|

|

|

|

|

|

|

|

Reports on the reliability etc will follow

|

|

|

|

|

|

|

|

|

|

|

|

|

LGB 12010 Turnout Motors

|

|

|

|

|

|

|

|

In contrast to the Böhler drives these throw the turnout points in a very rapid manner. A very audible “Clack” and the points are realigned; precisely the reason why I decided to use them at both Samedan and Thusis: the audible confirmation of the action.

|

|

|

That and the proven reliability of the drives — there must be many hundreds of thousands in operation around the globe. No further introduction necessary.

|

|

|

The throwbars of the scratchbuilt turnouts were easily adapted and using the ZIMO MX82(0)V decoders would allow both remote control (CTC) and local control via momentary centre-off toggle switches on a panel. Pretty well a KISS setup.

|

|

|

|

|

|

|

|

|

|

|

Mark 3 Handthrows

|

|

|

|

|

|

|

|

A KISS method to polarize handthrown turnouts.

|

|

|

|

|

|

|